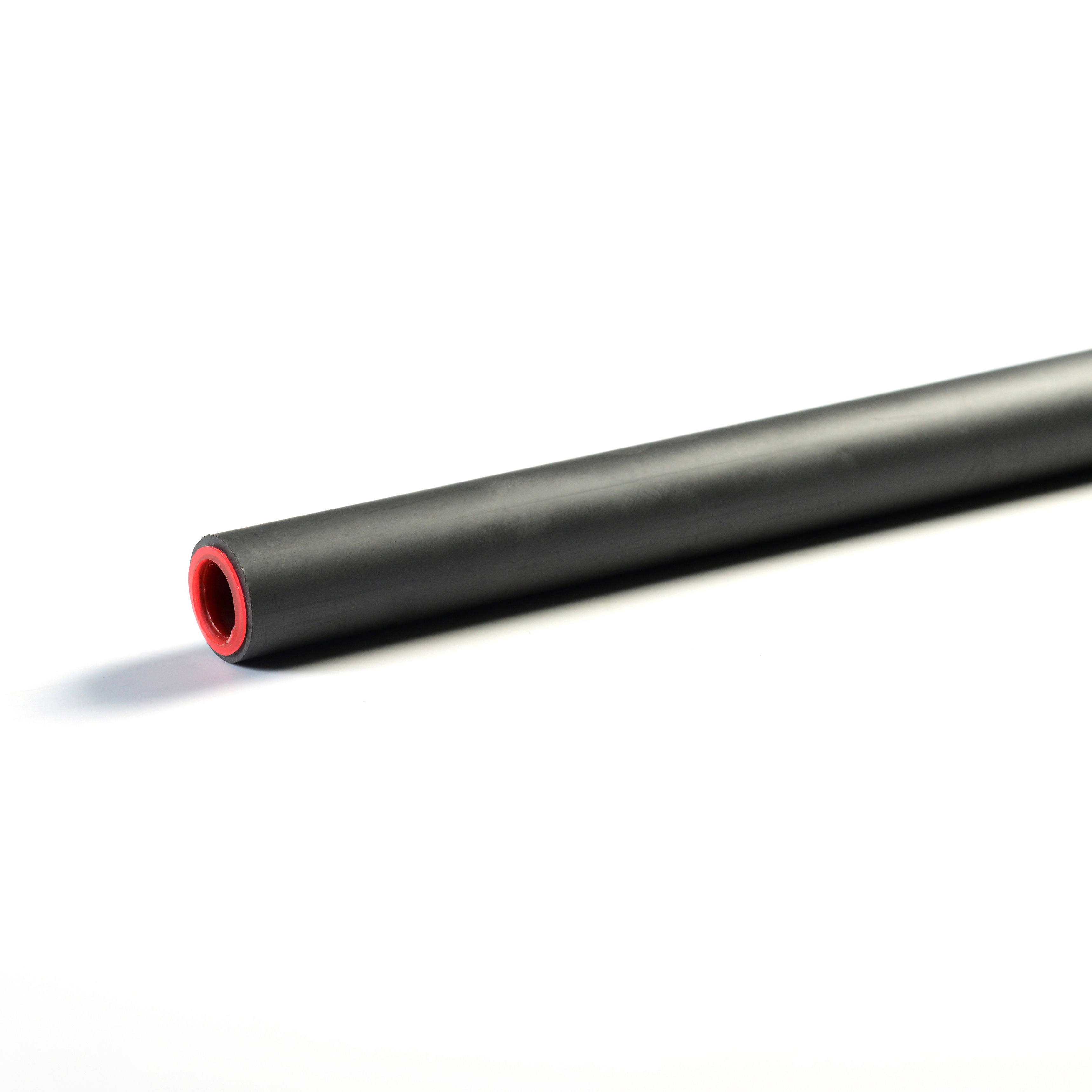

phosphat kongeedpaipujẹ iru opo gigun ti epo ti ko wọ wọ, eyiti o nlo ilana alayipo itẹ-ẹiyẹ alayipo.O jẹ akoso nipasẹ iṣẹ ṣiṣe ẹrọ ti alayipo itẹ-ẹiyẹ alayipo ti awọn ohun elo irin aise meji ti o yatọ, ni imọ-jinlẹ lilo sisanra paipu ita ita lati jẹri titẹ iṣẹ ti eto opo gigun ti epo, ati lilo paipu alloy alloy ti o ni ila lati ru awọn ibeere ibajẹ ti eto opo gigun ti epo.

Ti a fiwera pẹlu irin simẹnti alloy ti aṣa ti aṣa, irin simẹnti alloy ti ko wọ, irin seramiki pipọ paipu, ati paipu okuta simẹnti, phosphat pipe yiied paipu ni awọn anfani wọnyi.

1. Ti o dara yiya resistance.

2. Iwọn titẹ agbara giga, o dara fun awọn ipele titẹ giga.

3. Aṣọ inu inu ti wa ni wiwọ ni wiwọ pẹlu paipu irin ita, ati pe a yan ilana pataki kan lati ṣe idapọpọ idapọ laarin awọn ipele ti o wapọ, ti o ni idaniloju iṣẹ-ṣiṣe.

4. O ni o dara resistance to darí mọnamọna ati ki o gbona mọnamọna.

5. Asopọ ẹrọ ti o rọrun.Flanges ati awọn isẹpo rọ le ṣee lo fun asopọ, ati pe o le ge tabi welded ni ifẹ.

Iwọn lilo:

Eto gbigbe eeru erupẹ, paipu gbigbe eeru gbigbẹ tutu, ati eto eedu okuta ni awọn ohun elo agbara gbona

Awọn ọna gbigbe pneumatic miiran fun awọn patikulu lulú

Eto gbigbe slag hydraulic ati gbigbe gbigbe slurry pẹlu iwọn patiku nla

Gbigbe ti awọn oriṣiriṣi awọn ohun elo iwakusa

1. Phosphating ipa

(1) Ipa ti phosphating ṣaaju ki o to bo

① Imudara ifaramọ laarin Layer ti a bo (gẹgẹbi awọ awọ) ati iṣẹ-ṣiṣe.

② Imudara ipata resistance ti awọn dada ti a bo ti awọn workpiece lẹhin ti a bo.

③ Mu ohun ọṣọ dara si.

(2) Ipa ti kii bo phosphating

① Ṣe ilọsiwaju yiya resistance ti awọn workpiece.

② Rii daju didan ti awọn workpiece nigba ẹrọ.

③ Ṣe ilọsiwaju ipata resistance ti awọn workpiece.

2. Ohun elo ti phosphating

Irin phosphating jẹ lilo akọkọ fun aabo ipata ati bi fiimu ipilẹ fun kikun.

(1) Fiimu phosphating fun aabo ipata

① Fiimu phosphating aabo ni a lo fun itọju idaabobo ipata ti awọn ẹya irin.Iru fiimu phosphating le jẹ zinc tabi manganese.Iwọn fun agbegbe ẹyọkan ti awo ilu jẹ 10-40 g/m2.Waye epo egboogi ipata, girisi, epo-eti, ati bẹbẹ lọ lẹhin phosphating.

② Fiimu phosphating fun sobusitireti kun

Mu ifaramọ ati aabo pọ si laarin fiimu kikun ati awọn iṣẹ iṣẹ irin.Iru fiimu phosphating le jẹ orisun zinc tabi orisun kalisiomu zinc.Ibi-ipin agbegbe ti fiimu phosphating jẹ 0.2-1.0 g / m2 (ti a lo fun ipele isalẹ ti kikun lori awọn ẹya irin abuku nla);1-5 g / m2 (ti a lo fun ipele isalẹ ti kikun lori awọn ẹya irin gbogbogbo);5-10 g / m2 (fun ipilẹ kikun ti awọn ẹya irin ti ko faragba abuku).

(2) Fosfate ti a bo fun tutu ṣiṣẹ smoothness

Iwọn fiimu fun agbegbe ẹyọkan ti okun irin ati iyaworan paipu irin welded jẹ 1-10 g / m2;Iwọn fiimu fun agbegbe ẹyọkan ti iyaworan tube phosphating konge jẹ 4-10 g / m2;Iwọn fiimu fun agbegbe ẹyọkan ti extrusion tutu ti awọn ẹya irin jẹ tobi ju 10 g/m2.

(3) phosphate ti a bo fun idinku edekoyede

Fiimu phosphating le dinku edekoyede.Ni gbogbogbo, phosphating orisun manganese ni a lo, ati pe phosphating orisun zinc tun le ṣee lo.Fun workpieces pẹlu kekere ìmúdàgba fit ela, awọn ibi-ti awọn phosphating fiimu jẹ 1-3 g / m2;Fun awọn iṣẹ ṣiṣe pẹlu awọn ela ibamu agbara nla (awọn jia apoti gear), iwọn ti fiimu phosphating jẹ 5-20 g/m2.

(4) Fọsifate ti a bo fun idabobo itanna

Ni gbogbogbo, phosphating orisun zinc ti lo.Ti a lo fun itọju phosphating wafer silikoni ninu awọn mọto ati awọn oluyipada.

Akoko ifiweranṣẹ: Oṣu Kẹjọ-24-2023